- Home

- Quality Control

QUALITY IS OUR FOUNDATION

With the philosophy that quality first in mind,

LUMI sticks to do the right things:

Fit for purpose, right first time.

With the philosophy that quality first in mind, LUMI sticks to do the right things: Fit for purpose, right first time.

We Are Proven to Be Qualified

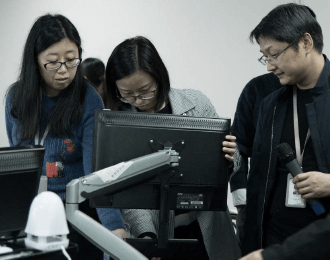

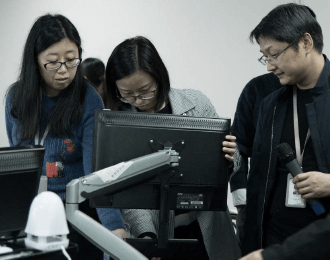

The Key to Our Success is LUMI Team

R&D Team

- 70+ engineers with 10+ years experience

- 1000+ patents

- 1000+ products awards high reputation among 400+ customers in 100+ countries longer than 8 years

- Move forward by attending regular trainings and advanced studies

- 70+ engineers with 10+ years experience

- 1000+ patents

- 1000+ products awards high reputation among 400+ customers in 100+ countries longer than 8 years

- Move forward by attending regular trainings and advanced studies

Quality Team

100+ QA/QCs in every step of quality control process

SQE

Coordinates process improve-

ments to the qualification

& production requirements of

factories

PQE

Product quality planning

and verification. Deal

with customers' compliant

IQCIncoming materials quality control

IPQCIn-process quality control

FQCInspect on finished products before storage

OQCLoading monitoring & Cargo examination

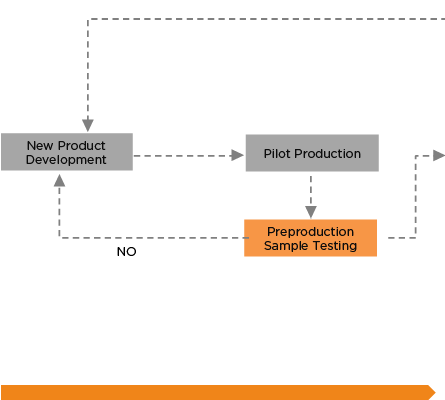

Always Conform to Standardized Process

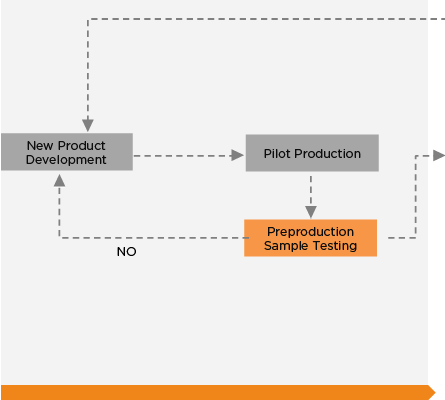

New Product Development Quality Control

Ensures the practicability and reliability of products with rational design and customer demands at the beginning of products development. Tests every sample and detects every flaw in the design stage prior to mass production.

Launch the Project

R&D team work with in-depth analysis to avoid unreasonable design

Prototype Test

Test the functionality and reliability of samples in full depth

Mold Sample Test

Test the functionality and reliability of samples in full depth

Pilot Production

The final step before mass production

Trace First Feedback

Trace customer feedback about new samples to improve the quality

Project Completed

Review and solve all problems in the whole develop stage to ensure mass production

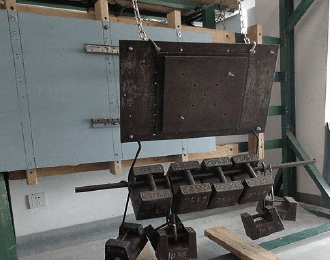

Four-stage Preproduction Sample Testing

- Function test

- Load capacity test

- User experience

- Function test

- Package test

- User experience

- Trace & solve the problems to ensure mass production

- Collect users' feedback about new samples to improve the design and quality during the whole stage

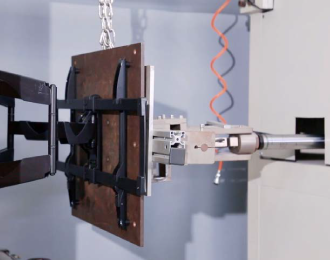

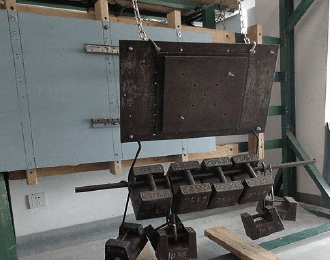

Professional In-house UL/TUV Witness Test Labs

- Wood Stud Wall

- Concrete Wall

- Wooden Wall

- Salt Water Spray Test

- Temperature Test

- Paperboard Burst Strength Test

- Transit Test

- Carton's Crush Resistance Test

- Carton Drop Test

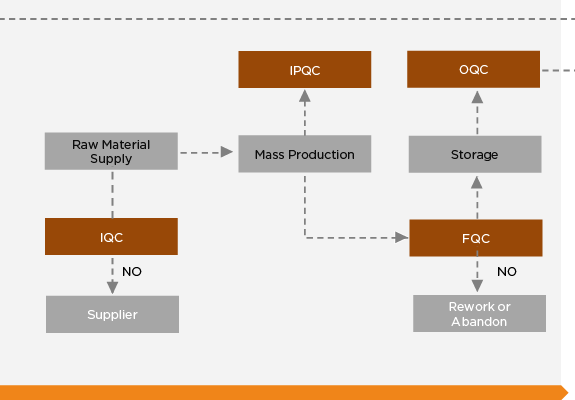

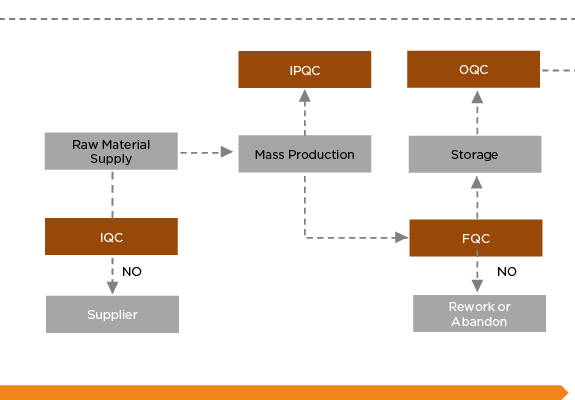

Mass Production Quality Control

Reviews and analyzes the data collected while monitoring production to improve quality, increase yield and minimize postponement incidents.

Incoming Quality Control

We not only select about distributors, but also about incoming materials

In-Process Quality Control

Inspections will be done in various forms during in-process production

Finished Quality Control

When finished, product and packaging will be inspected

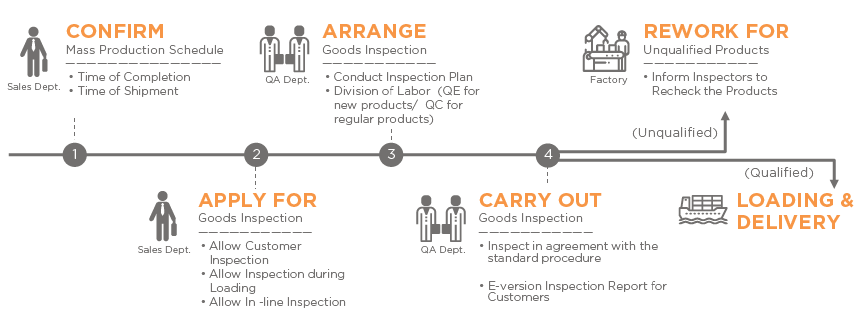

Outgoing Quality Control

The last inspection before shipment

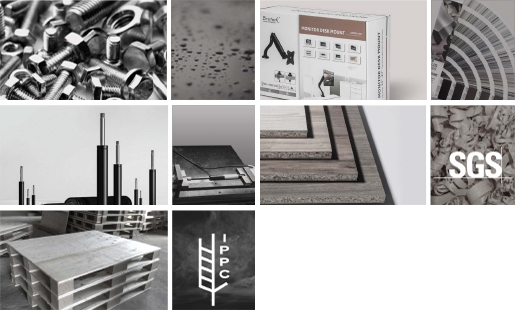

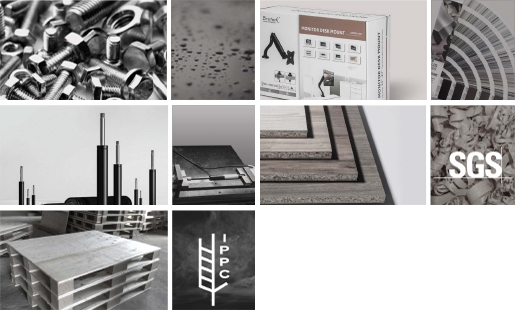

Incoming materials quality control

- Metal Components

- Gas Spring

- Quality MDF Board

- Color box

- Wooden Pallet

- Pass the Salt Water Spray Test to avoid corrosion

- Pass the strength test to approve the performance

- EPA TSCA TITLE VI Certificate for approving

- Use Pantone color card to control the color difference

- IPPC certified to ensure the transport security

Keys to Secure Quality

- Implementing 6S management

- Complete SOP in each process

- IPQC inspection during the whole production

(First article - Routing - Final)

Finished Quality Control

- Before warehousing,

the finished products need to be

spot checked according to

AQL standard.

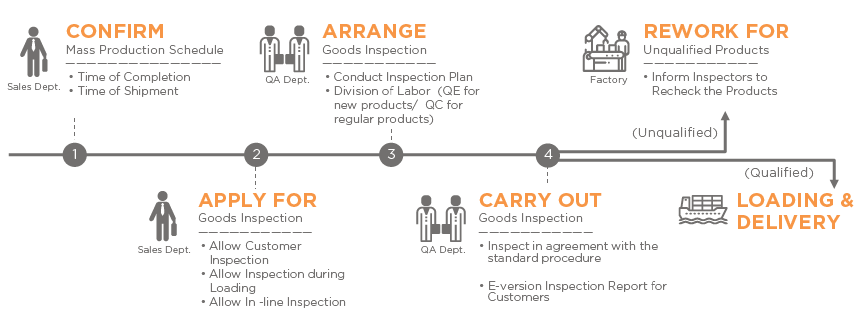

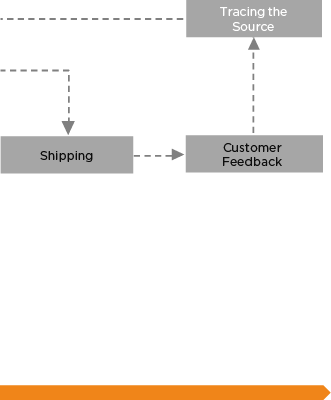

Outgoing Quality Control

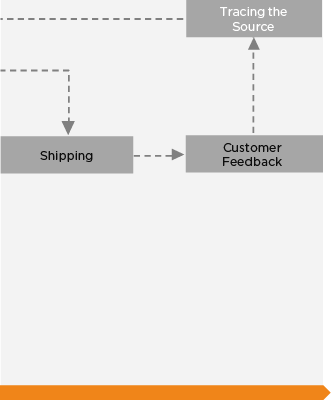

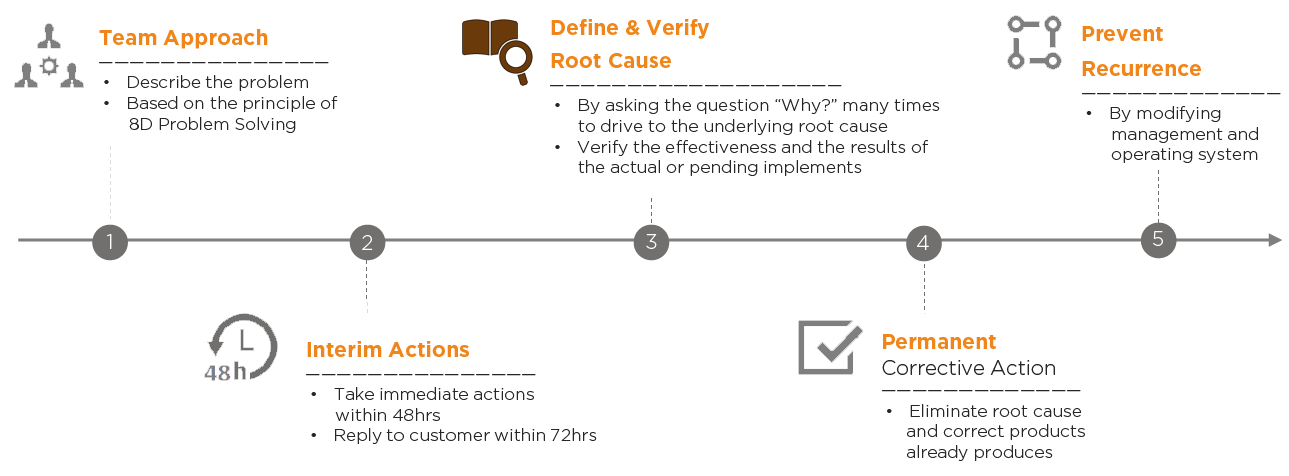

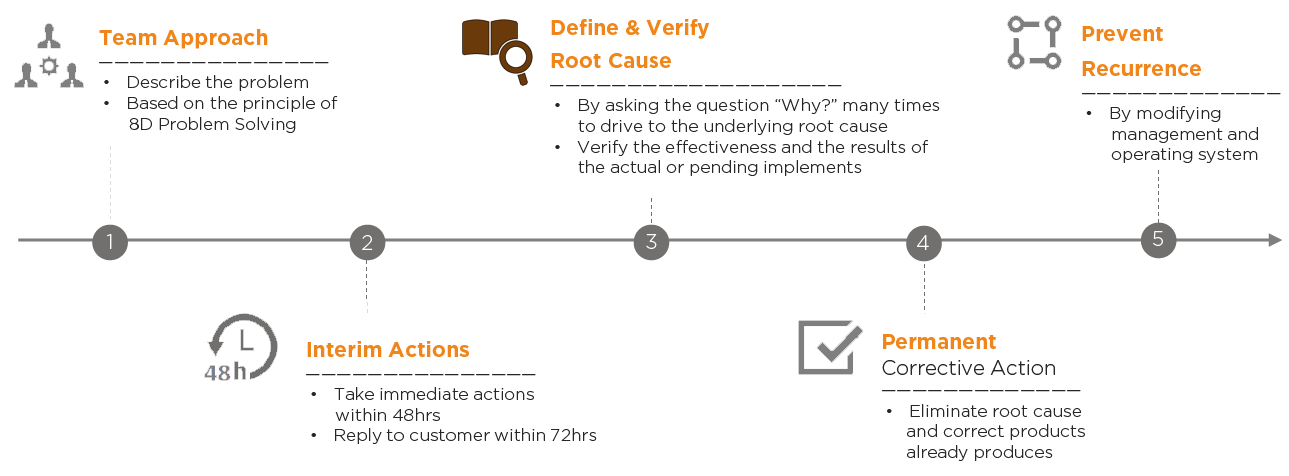

After Sales Quality Control

Consistently utilized in the development of new products based on customers' feedback and market data.

Periodic Review

Periodic meeting (monthly,quarterly,semi-annually and yaerly) will be held to be analyze the statisics and formulate the periodic improvement plans.

A Database of Quality Control

Graphic statiscis give a clear reflection on current quatily control situation.

Regular Trainings

- Skill Training

- New Product Training

- Quality Standard Training

Launch the Project

R&D team work with in-depth analysis to avoid unreasonable design

Prototype Test

Test the functionality and reliability of samples in full depth

Mold Sample Test

Test the functionality and reliability of samples in full depth

Pilot Production

The final step before mass production

Trace First Feedback

Trace customer feedback about new samples to improve the quality

Project Completed

Review and solve all problems in the whole develop stage to ensure mass production

Four-stage Preproduction Sample Testing

- Function test

- Load capacity test

- User experience

- Function test

- Package test

- User experience

- Trace & solve the problems to ensure mass production

- Collect users' feedback about new samples to improve the design and quality during the whole stage

Incoming Quality Control

We not only select about distributors, but also about incoming materials

In-Process Quality Control

Inspections will be done in various forms during in-process production

Finished Quality Control

When finished, product and packaging will be inspected

Outgoing Quality Control

The last inspection before shipment

Incoming materials quality control

- Metal Components

- Gas Spring

- Quality MDF Board

- Color box

- Wooden Pallet

- Pass the Salt Water Spray Test to avoid corrosion

- Pass the strength test to approve the performance

- EPA TSCA TITLE VI Certificate for approving

- Use Pantone color card to control the color difference

- IPPC certified to ensure the transport security

Keys to Secure Quality

- Implementing 6S management

- Complete SOP in each process

- IPQC inspection during the whole production

(First article - Routing - Final)

Finished Quality Control

- Before warehousing,

the finished products need to be

spot checked according to

AQL standard.

Outgoing Quality Control

Periodic Review

Periodic meeting (monthly,quarterly,semi-annually and yaerly) will be held to be analyze the statisics and formulate the periodic improvement plans.

A Database of Quality Control

Graphic statiscis give a clear reflection on current quatily control situation.

Regular Trainings

- Skill Training

- New Product Training

- Quality Standard Training