How long has LUMI been in business and how many employees do you have?

Established in 2005, LUMI now has over 500 professionals at our Yinzhou (NINGBO, CHINA) headquarters office building. With multiple factories, our workers now total in thousands.

What is LUMI's turnover on domestic market vs. export markets?

What should I do if I cannot find the products that I need?

What should I do if I have questions about your products?

Why should I buy from LUMI?

How can I receive monthly updates of LUMI new products?

How old are LUMI factories? When did you first start manufacturing?

How large are LUMI factories and what capacity do the factories have?

How does the production process work?

How are the factory workers trained and are they experienced?

Are LUMI factories audited?

Is LUMI an ISO rated company?

Is LUMI in adherence to Labor and Environmental laws?

Has LUMI been audited for Social Compliance?

Do LUMI products fall under the European CE Directive and if so do they carry the CE Mark?

Do LUMI products receive TUV GS certification?

Are LUMI products UL certified?

What is the UL Witness Test Data Program?

What kind of certification does LUMI have related to the environment and social responsibility?

Will LUMI mounts hold the stated weight?

Do LUMI products comply with USA California Proposition 65 "Prop 65"?

How does the factory control the incoming components?

How does the factory do the in-process QC?

How does LUMI do final QC?

Does LUMI send samples for testing in a laboratory?

What is the lead time for samples and normal order?

Do I have to pay for samples?

How are samples shipped?

What about duty, VAT or customs on samples?

Will English installation manual include in packaging? Is customized manual available?

What is the standard packaging? Can I have a packaging of my own?

What Warranty (Guarantee) is offered on LUMI products?

How do I become a customer of LUMI's?

How do I obtain pricing on products I am considering purchasing

What are your payment terms?

Are my payment terms negotiable?

Do you have a volume rebates or incentive programs?

Under what circumstance might prices change?

Here are a few online resources that will assist you in tracking and understanding these issues:

· commodity tracking for steel and aluminum

· currency exchange rates

Is LUMI an OEM or ODM company, and what is the difference between an OEM and ODM product/project?

· OEM stands for Original Equipment Manufacturing and refers to products that are fully designed by LUMI that we customize/brand for our customers to sell into their markets.

· ODM products are conceived and designed by LUMI customers. However, LUMI offers assistance in the ODM product development process due to the expertise and internal resources we have available. This includes mechanical, electrical engineering, and industrial design ability.

How can I be certain LUMI will not sell my proprietary product to others?

What information is needed to begin an ODM project with LUMI?

Will LUMI assist me in patenting or protecting my product from potential infringement?

I am a small company or inventor and I am seeking a partner to make my idea/product. Can LUMI help me?

Does LUMI have custom capabilities?

Does LUMI have R&D facilities and prototyping?

What CAD and Design Compatibility does LUMI have?

What resources does LUMI have in the following engineering areas?

What happens if materials don't arrive?

Can LUMI assist me in importing the product into my country?

1. D.I.Y. – Manage Your Own Freight for Full Control

New to novice-level importers typically choose this freight management process. The pro to this option is that all you have to do is instruct LUMI to ship cargo as CIF "Port of Destination" or DAP "Your facility Address".

2. Work with a Freight Forwarder

This is the most convenient option for companies that purchase from LUMI. Companies also tend to prefer the idea of working with a freight forwarder that's based on their home turf for extra peace of mind, more transparency, and faster communication. Using a freight forwarder may increase your overall cost when importing products into your locations.

· FOB (Freight on Board)

This is the most popular method for importers/buyers of LUMI. We are responsible for transporting goods from their place of origin and having the goods loaded onto the vessel at the container port. Once loaded onto the China shipping container, the risk of loss or damage transfers from LUMI to the importer/buyer. From this point on, the importer is responsible for all insurance and transportation costs. It will also be the importer's responsibility to ensure goods clear customs. This method is known to be one of the cheapest ways to ship from China to the USA.

· CIF (Cost Insurance Freight)

LUMI is responsible for the transportation of goods from the place of origin to the port of destination. LUMI is also responsible for purchasing insurance on behalf of the importer/buyer. However, once loaded onto the vessel, the importer/buyer will assume any risk of damaged or lost goods and will need to file an insurance claim in such a case.

· CFR (Cost and Freight)

LUMI is responsible for the transportation of goods to the port of destination along with all associated costs. Liability is transferred to the importer/buyer once goods are placed on board the vessel. The importer/buyer is responsible for payment of port handling costs at the port of destination and land or rail transportation to the destination warehouse.

· OTHER

Contact your LUMI Representative should you require any other type of delivery requirements.

Can LUMI assist me in filing USA's Import Security Filing (ISF) -10+2 form?

Does LUMI ship less than a container of products?

How long will it take for my product to reach me after LUMI ships my goods?

Normally, the time it takes to ship from China to the United States may vary slightly depending on the destination port. West coast cities such as Los Angeles, Oakland, and Portland have an approximate lead time of 20 days. East coast cities such as Miami, Jacksonville, Baltimore and New Jersey have lead times of approximately 30 days. It's doesn't happen often, but there may be a scenario where there's an issue with a container ship after it has left the port of origin. In a cumbersome situation such as this, another 10 – 15 days may need to be added to the lead time. NOTE: It is in these cases that a freight forwarder can be quite helpful.

Can LUMI help me source products that I don't see on the LUMI.cn website?

LUMI Vida offers a two-fold solution for customers:

· LUMI Vida is your sourcing service for products purchased outside LUMI's supply chain. Offering full testing and evaluation of products, clear communication and low prices.

Visit LUMI Vida for more information

Can LUMI provide me with marketing materials such as images, brochures, videos and other things to help me sell the products?

Can LUMI create customized marketing material for my company?

Can LUMI help me sell on Amazon?

Glossary of import/export terminology

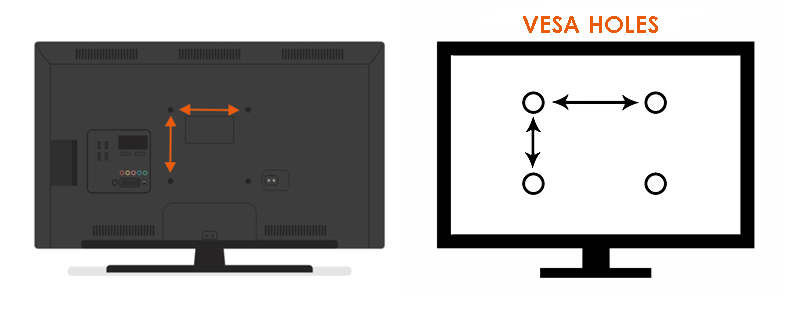

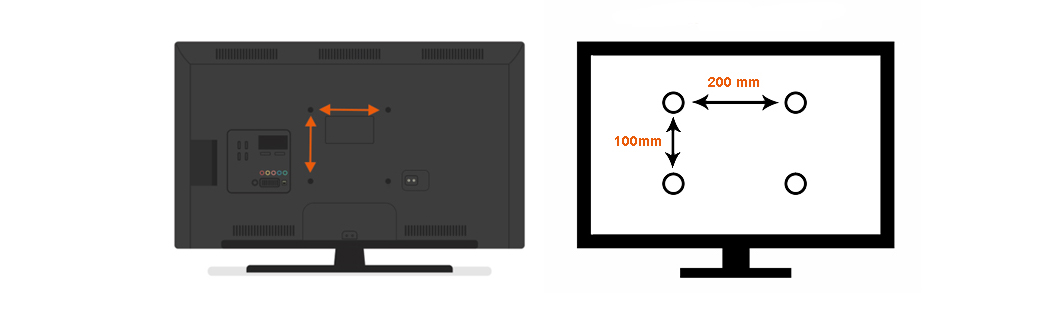

What are VESA holes or VESA hole patterns?

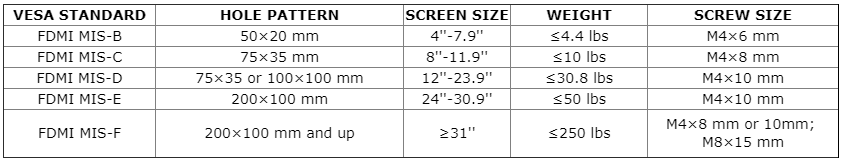

LUMI complies with a set of standards set by the VESA Association known as the Flat Display Mounting Interface (FDMI) or Mounting Interface Standard (MIS). This makes it easy to choose a mount that can accommodate and safely hold your display.

What is standard VESA hole patterns? How to decide whether the mount fits my TV?

The mounting holes are in the back of a TV and the TV weight determines the exact mount that will fit a TV. LUMI suggests that the consumer determine the weight and mounting hole distance of their TV prior to selecting a suitable mount.

| VESA Hole Patterns | Recommended TV Size |

| 100×100 | 13''-27'' |

| 200×100 | 13''-32'' |

| 200×200 | 23''-42'' |

| 400×200 | 32''-55'' |

| 400×400 | 32''-55'' |

| 600×400 | 37''-70'' |

| 800×400 | 37''-70'' |

| 800×600 | 37''-70'' |

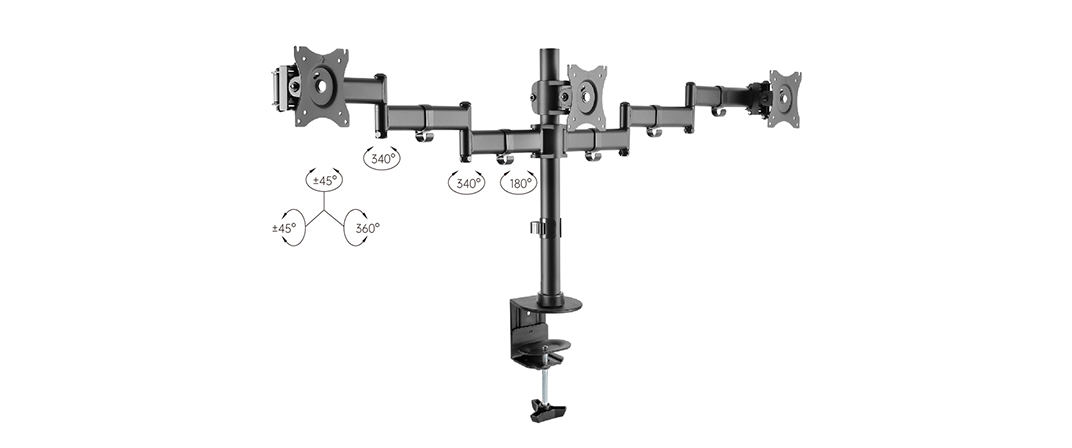

What are brackets or arms?

What does articulating mean?

What does full motion mean?

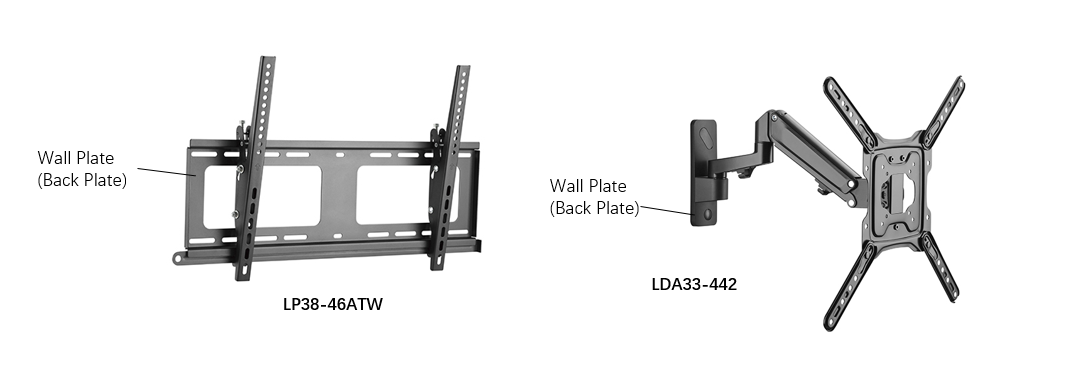

What is a back plate or wall plate?

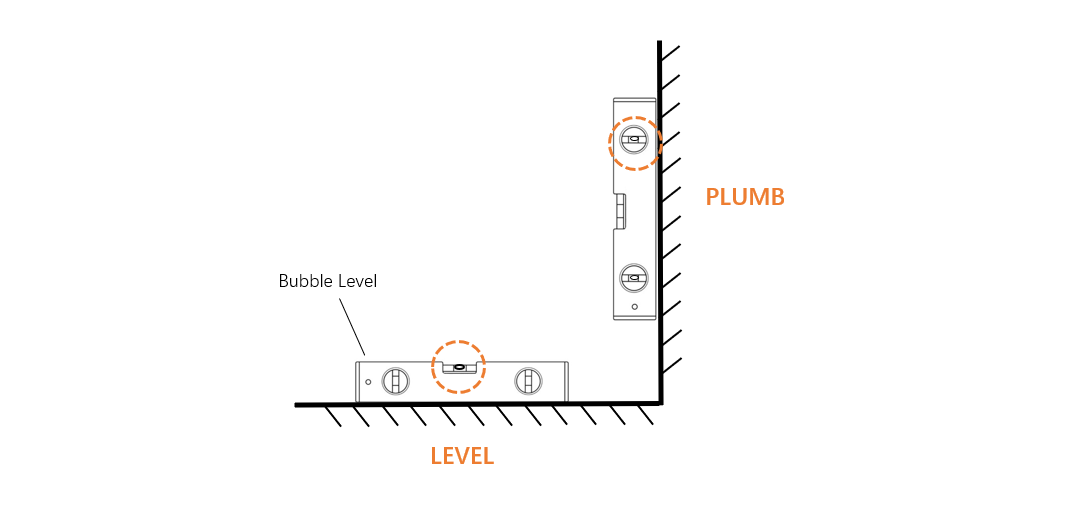

What does plumb or level mean?

What is the most common distance between wood studs?

What is the difference between drywall and sheetrock?

What is the normal width and thickness of drywall in the USA and Canada?

What does Tested 3X or Tested 4X mean?

What is a vertical or portrait mount?

What is a horizontal or landscape mount?

What is an Allen key?

What is a nut driver?

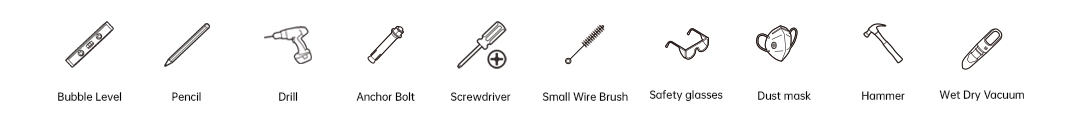

What tools are required to install a TV mount?

1. On wood, drywall, or sheetrock walls, you need to prepare:

2. On a brick, cement, stucco, concrete block, and stone walls, you need to prepare:

3. Into a wall without studs, you need to prepare:

What are M-rated screws used for?

What are anchor or expansion bolts?

What are the differences between gas spring, mechanical spring, mechanical and spring-assisted monitor arms?

Gas springs rely on a pressurized gas to store energy. The nitrogen is compressed in an enclosed cylinder and the output force of the gas spring depends on the amount of pressure applied over the gas chamber.

Mechanical spring/spring-assisted monitor arms – for long product lifetimes

Spring-assisted monitor arms are also called mechanical spring monitor arms. The function of height adjustment is achieved by mechanical springs, which are conventional coiled-metal springs. They rely on elastic deformation to store energy when compressed.

Mechanical/articulating monitor arms – for the most competitive cost

Mechanical monitor arm is another name for articulating monitor arm. They don't have springs in the arm assembly. Instead, the articulating joints allow the user to adjust the height, tilt, pivot and rotation of the monitor arm to reach a comfortable ergonomic position. It is the most affordable solution to provide flexible viewing adjustment.

| Gas Spring Monitor Arms | Spring-Assisted (Mechanical Spring) Monitor Arms | Mechanical (Articulating) Monitor Arms | ||

| Adjustment | Performance | Effortless and Smooth | Smooth | N/A |

| Release Force | Slower and Controlled Release Force | Stronger Release Force | ||

| Operation Noise | Very Quiet | Quiet | ||

| Arm Size | Oversized | Standard Size | Slim | |

| Cost | Slightly Higher | Median Priced | Affordable | |

| Life Span | Long Life | Very Long Life | Longest Life | |

| Environment Friendliness | Should be Recycled | Recyclable | Easily Recyclable | |

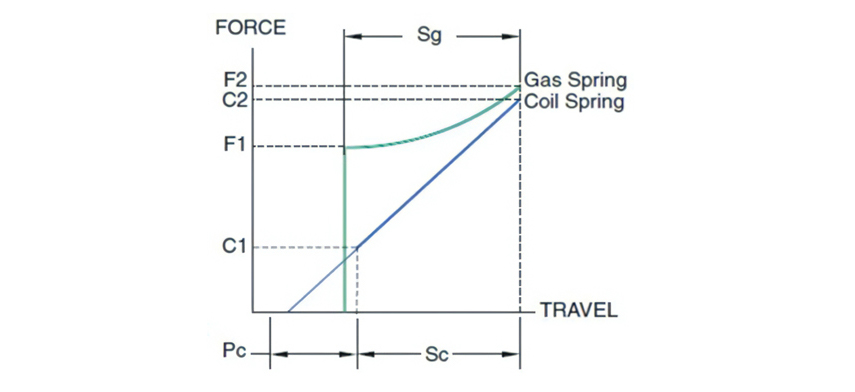

What's the difference between gas cylinder and spring coil counterbalance mechanisms in monitor arms?

Coil springs are used primarily because they are more economical, and have no parts to fail or seals to leak so they also have extreme longevity. This means their force will remain constant as the years go by. They're not as smooth or silent as gas cylinders, and they have a faster "kick back" (stronger release force). The counterbalance forces increase linearly as the spring coils are compressed (see graph below). The force rendered by a spring coil depends on its material, wire thickness, spring diameter, number of coils and length.

Gas cylinders are used primarily for their smooth and silent operation, but they cost a little more and have a moderate lifetime compared to springs. Gas cylinders have a slower "kick back" (controlled release force), and force increases exponentially as they are compressed. It takes less force to compress the system at the beginning of the stroke, at the end of the stroke it requires much more force (see graph below). The force rendered by a gas strut depends on its internal pressure.

Gas vs. Coil Spring "Kick Back" (Release Force)

Summary

| Coil Springs | Gas Cylinders |

| More economical | Cost a little more |

| Extremely long product lifetimes | Moderate lifetime |

| Not as smooth or quiet in operation | Smooth, silent operation |

| Faster "kick back" (strong release force) | Slower "kick back" |

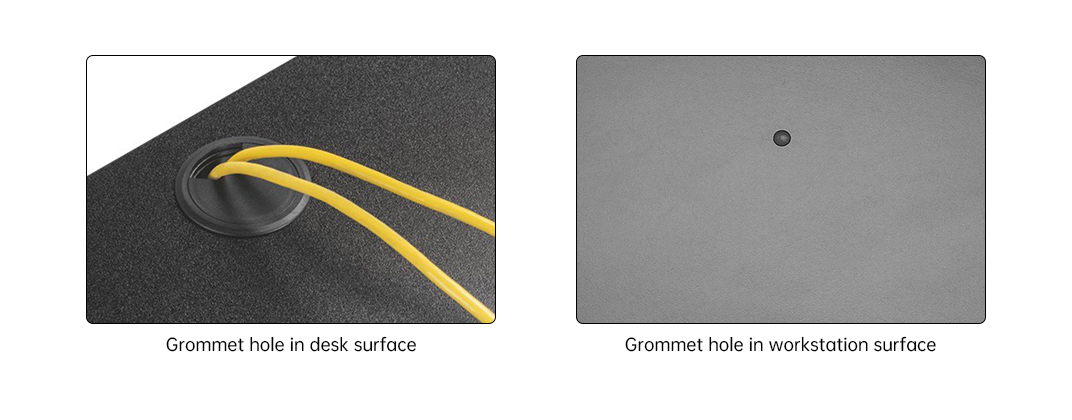

What is a grommet hole?

There are two types of grommet holes: The larger one is normally 2" and used to pass the cable through as well as mount the arm in a grommet configuration. The second grommet hole is smaller and normally found on workstations (desktop converters) and used strictly to mount an arm to the device.

What is a grommet mount?

What is a clamp mount?

What does counterbalance mean?

What is a smart stand?

There are two ways to use the smart stand:

1. Connect the smart stand with a PC. In this way, the smart stand becomes a USB expansion of the computer. Data and audial signals can be accessed easily by plug in flash drives or headphones into the ports.

2. Connect the smart stand with the power and these ports can be used for charging devices.

What are multimedia ports?

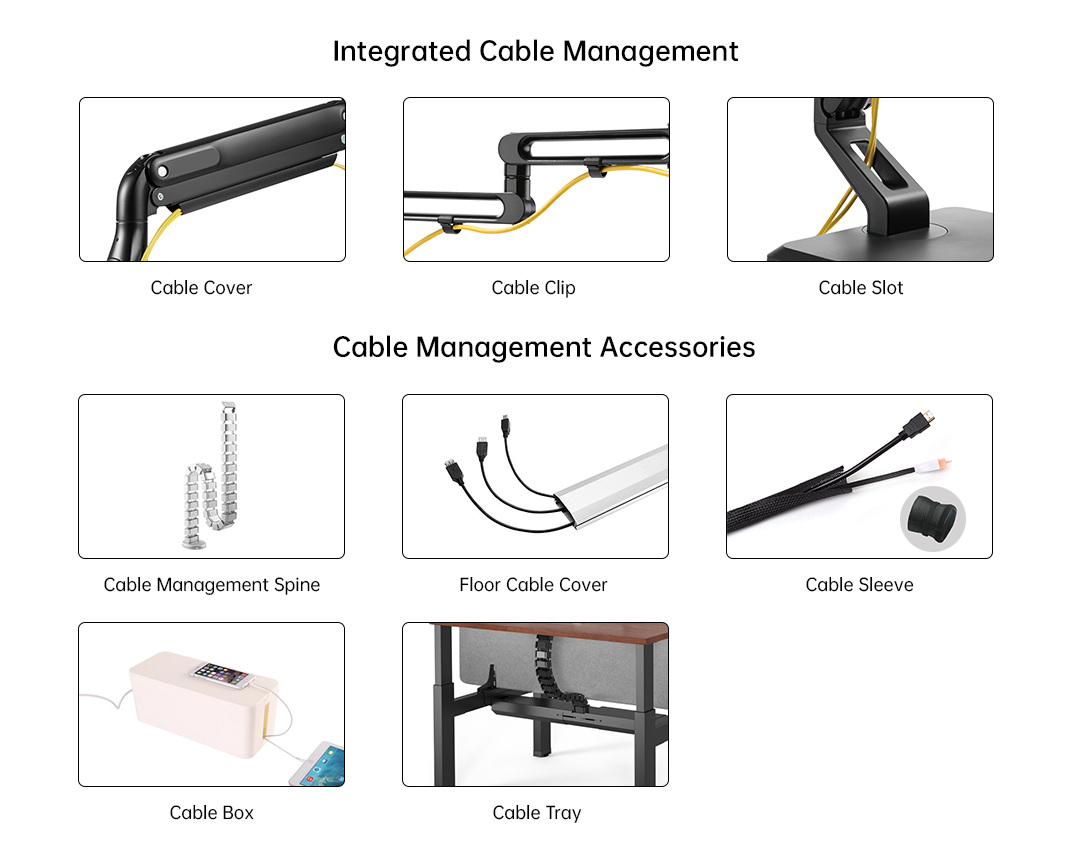

What is cable management?

Discover Inspiring Cable Management Accessories Right Here

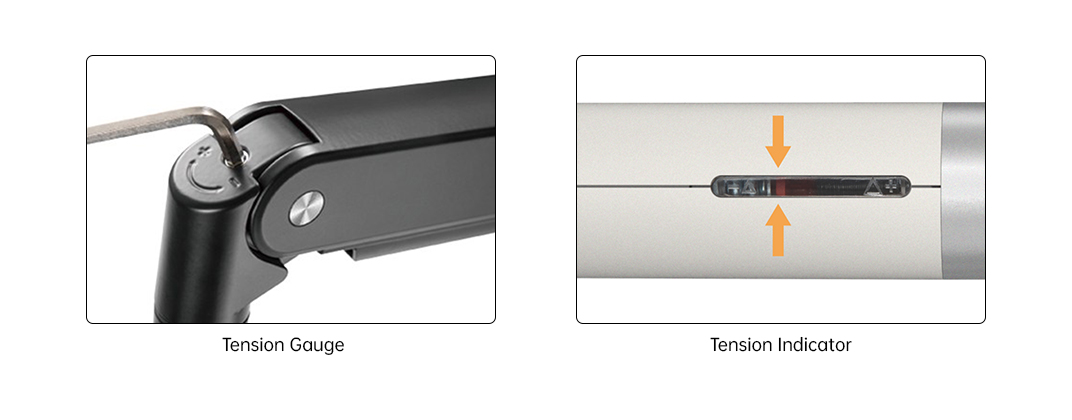

What is a tension gauge or weight indicator and how do they benefit the installer?

One additional question may be, how is the tension adjusted? A screw can be found on the arm for tension adjustment. With an Allen Key, users can easily tighten or loosen the screw until the monitor is perfectly balanced and firmly holding the weight of the monitor.

The built-in tension gauge allows the user to mount any screens within the weight capacity. When installing multiple monitors the tension indicator can be used to balance monitors by referencing the balance point when the same make/model of a monitor is used throughout the multi-monitor installation.

What is a rotation stop?

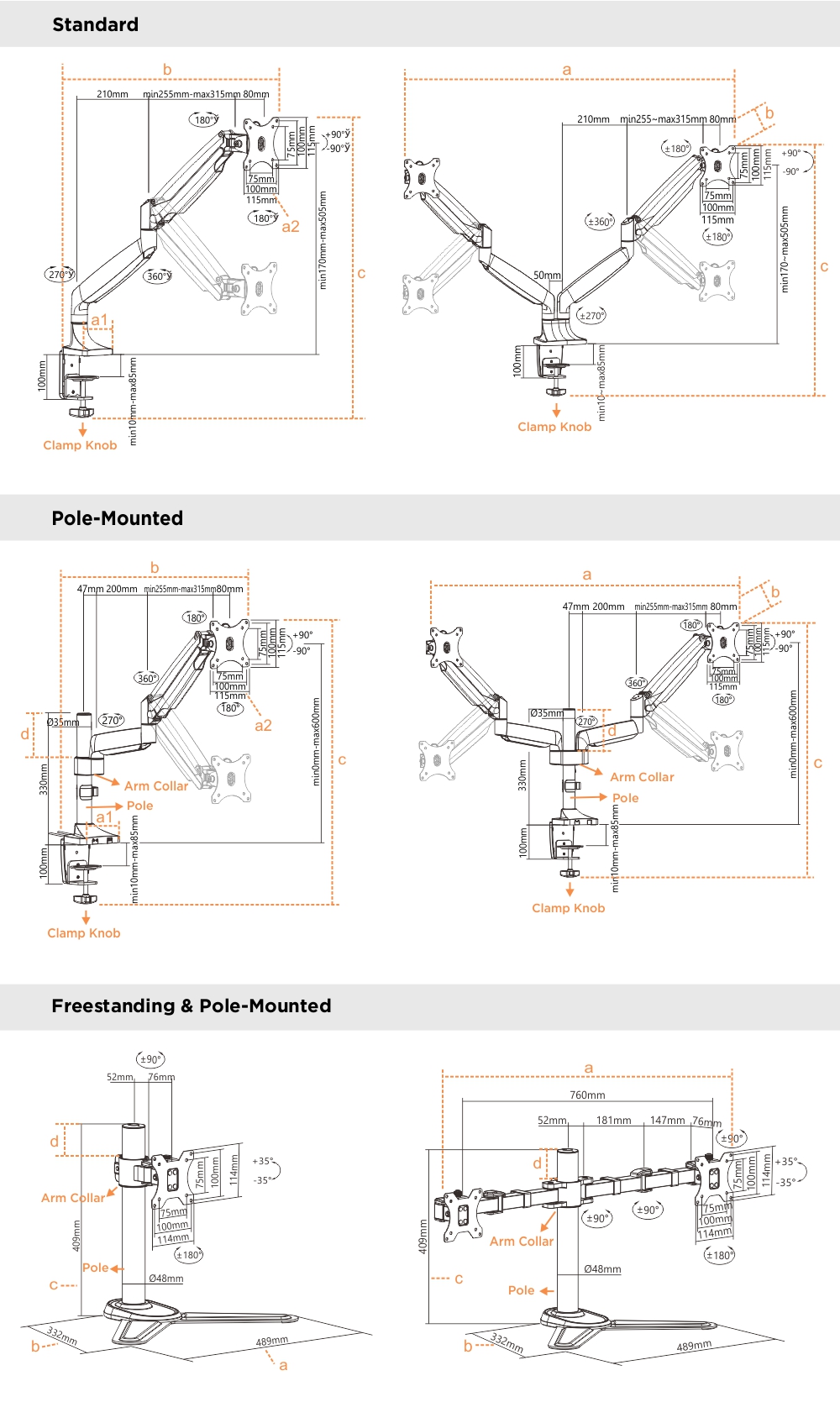

What are product dimensions of monitor arms and how to measure them?

Measurement Standards: Dimensions are measured with the arms fully extended, the VESA plates facing forward and the Clamp Knob located on the base tightened. *If the monitor arm is with a pole, d=0 (the distance from the top of the Pole to the top of the Arm Collar of the suspended arm)

Width a: The straight-line distance from left to right. (Take the greater one between a1 and a2.)

Depth b: The straight-line distance from front to back.

Height c: The straight-line distance from top to bottom.