PRODUCTION PROCESS

LUMI factories are equipped with modern facilities for high-efficiency and safe manufacturing. Regular trains and detailed SOP given to the workers ensure standardized operations while reducing mistakes. Comprehensive security precautions maintain workers and product's safety. In addition, a variety of tests carried out during production guarantee the quality of products.

Stamping

Stamping (also known as pressing) is the process of forming a flat sheet metal into a specific shape.

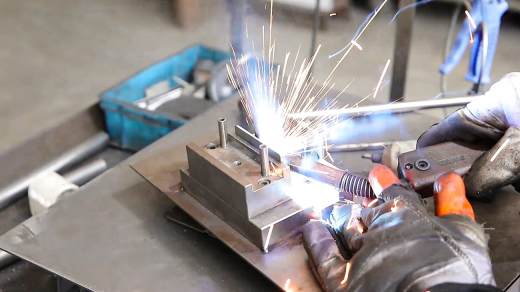

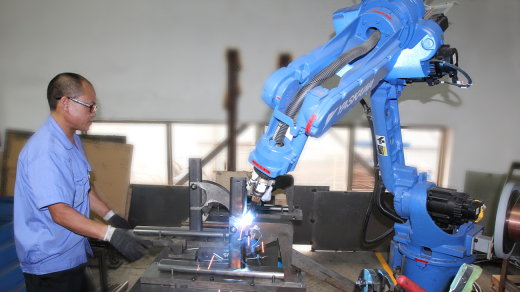

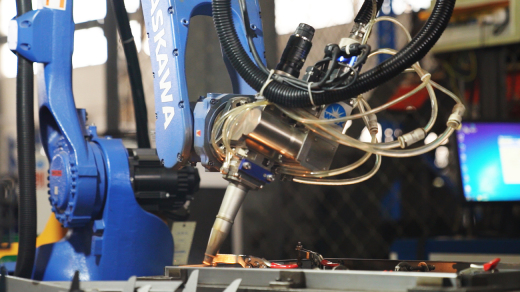

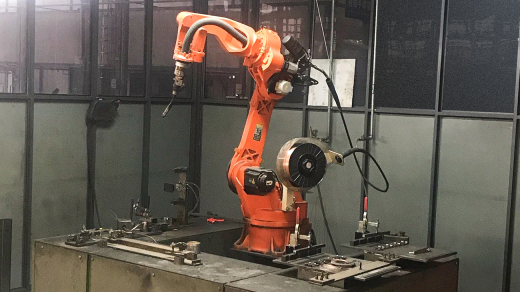

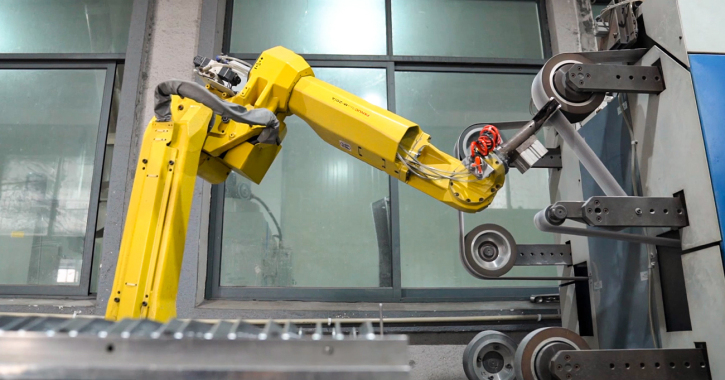

Сварка

Welding is a fabrication process that joins materials by using high heat to melt the parts together and allowing them to cool, causing fusion.

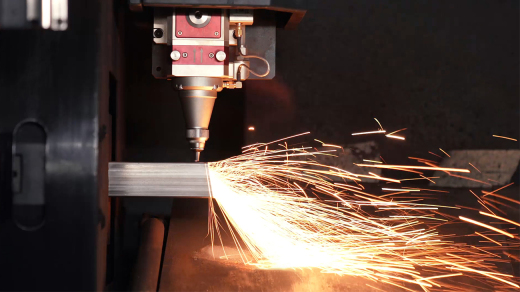

Cutting

Cutting is the process of producing a work piece by removing unwanted material from a block of metal, in the form of chips.

Die-Casting

Die-casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mould cavity.

Polishing

Polishing is the process of creating a smooth and clean surface by rubbing it or by applying a chemical treatment.

Coating

A coating is a layer of material deposited onto a substrate to enhance the suface properties for corrosion and water protection.

Manual Assembly

Assembly is a process in which parts are added in sequence from workstation to workstaion until the final assembly is produced.

Semi-Automatic Packaging

Packaging is a coordinated system of preparing goods for transport and warehousing.

Safety Test

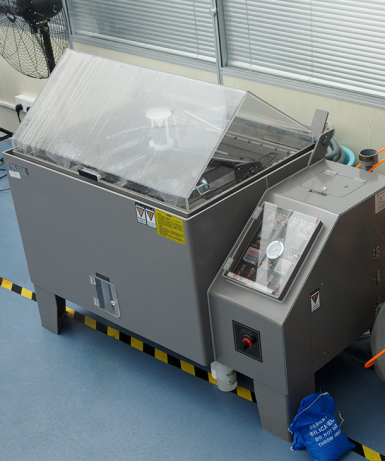

- Slope Test

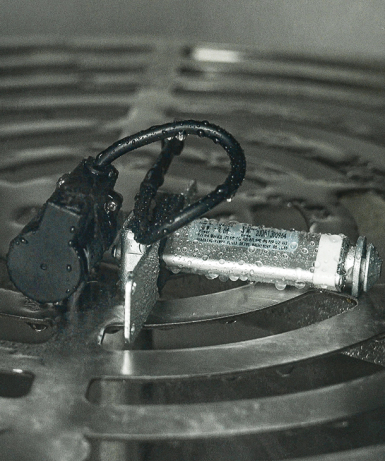

- Salt Spray Test

- IP Test

- Noise Test

Function Test

- Testing Lab

- Standing Desk Loading Test

- TV Mount Loading Test (Stud Wall)

- TV Mount Loading Test (Solid Wall)

- Spring Tension Value Test

Life Test

- Desk Converter Fatigue Test

- TV Wall Mount Fatigue Test

- Gas Spring Fatigue Test

- Caster Endurance Test

- Electric Controller Life Test

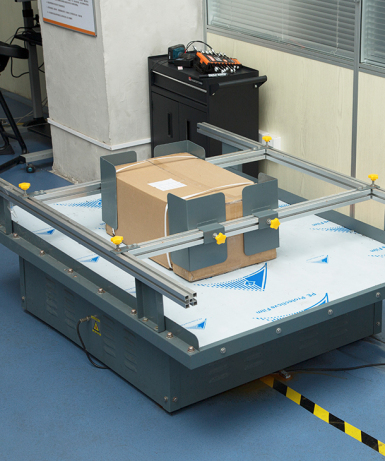

Transport Condition Test

- Paperboard Burst Test

- Compression Test & Dropping Test

- Shock Test

CERTIFICATES

We are certified by ISO 9001, ISO 14001, BSCI and Sedex.